January 16, 2024

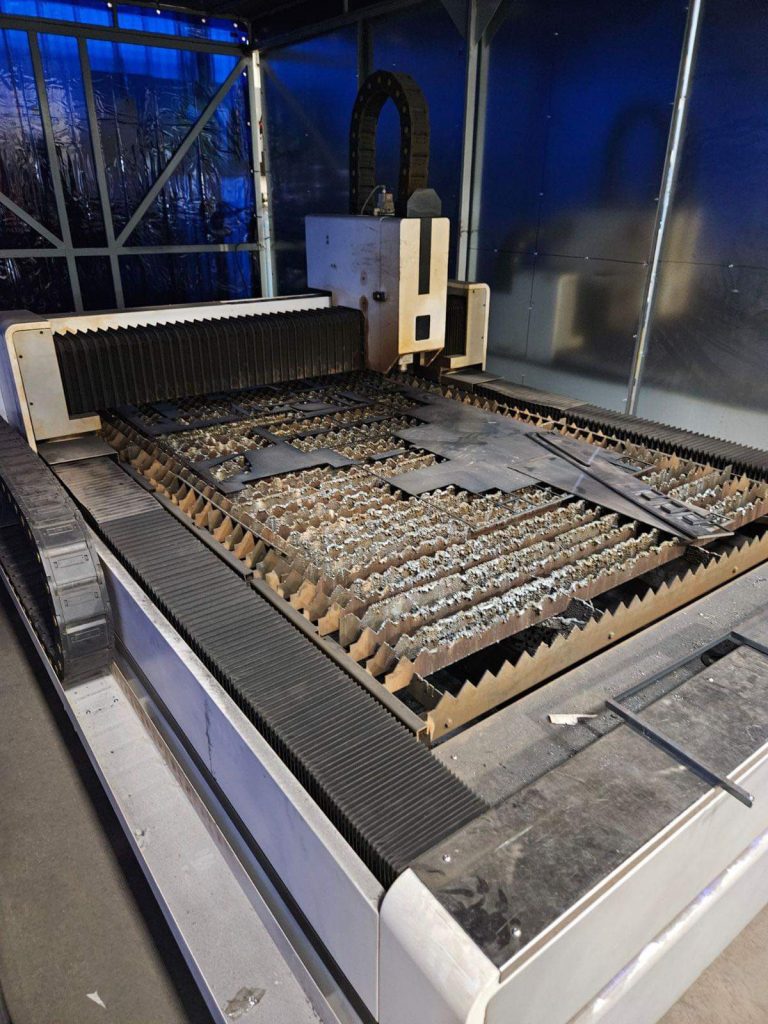

We’re proud to have equipment that enables us to be efficient and effective. This includes our new laser cutting table, which plays a vital role in our tank manufacturing process.

Its unrivalled precision cutting eliminates the need for unnecessary welding, which was traditionally used to assemble components.

In fact, there are two advantages to using a laser cutting table:

- It considerably reduces production costs, since welding is a time- and labour-intensive process ;

- It improves the quality of the final product by eliminating potential weld imperfections.

As a result, we are now able to create products in a variety of shapes and sizes, within competitive lead times, to meet the specific needs of a market that is increasingly demanding customized products.

At the same time, using the laser cutting table has enabled us to raise our productivity levels when it comes to mass production.

Indeed, our designers can now rapidly create prototypes to validate and test their ideas, reducing the time taken in the product development process. What’s more, our designers ensure that the final products meet our customers’ requirements.

Finally, the arrival of our laser cutting table gave us the opportunity to change the role of our operators, who also became supervisors, programmers and laser machine operators. They are therefore more involved in high value-added tasks.

The arrival of the laser cutting table is tangible proof that Biexo is constantly seeking to invest in the acquisition of new high-performance equipment, and that its staff work every day in a modern, high-performance workshop at the cutting edge of technology. This enables the company to continually improve its service offering and enhance the quality of its products.

Do you have any questions ? We have the answers ! Contact us now to discuss your project.